Kito Crosby

Kito Crosby is a specialist in the innovation, manufacture and distribution of products and services used to make lifting and load securement safer and more efficient. With global engineering, manufacturing, distribution and operations, the company provides a broad range of products and solutions for the most demanding applications with uncompromising quality that exceeds industry standards.

Chosen for this store are its range of shackles, SpeedBinders, wire rope clips, turnbuckles, McKissick blocks and CrosbyIP clamps and magnets. The company has invested many resources into helping end user markets overcome common challenges, including lowering costs by providing reusable, longer-lasting equipment. The breadth of product range delivers solutions to end user markets at varying points of a supply chain, including manufacture, transportation, installation, maintenance and training.

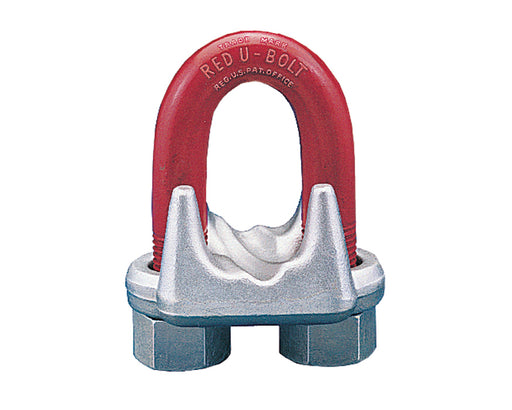

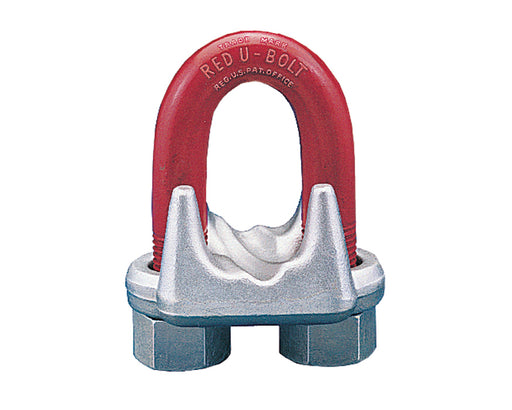

Its shackles, for example, are commonly used to connect the slings or load to a winch or crane block. The shackle is one of the most powerful, important, irreplaceable pieces of material handling equipment there is. Shackles are one of the most versatile pieces of equipment in nearly every rigging, lifting and material handling operation because they serve the critical function of connecting various pieces of lifting equipment to the load. Crosby wire rope clips, meanwhile, are used in a myriad of applications to clamp the loose end of a length of wire rope, once it has been looped back to form an eye. Shackles and wire rope clips are just two standout products in our comprehensive Crosby portfolio.

The company is set apart on numerous levels because of a breadth of product range, its availability close to the point of use, and, importantly, its enviable status as a 95% vertically integrated manufacturer. Vertical integration provides complete control of the manufacturing process from raw material to finished goods. This control ensures product inspection throughout the process, affording a high level of quality and consistency across all product lines. It gives a manufacturer control over supply chain and quality of raw material source; internal engineering; product innovation and new product research and development; proximity to industry trends; control of product scheduling and manufacturing process; and much more.

Filters

-

Sale

from $142.99| /

Sale

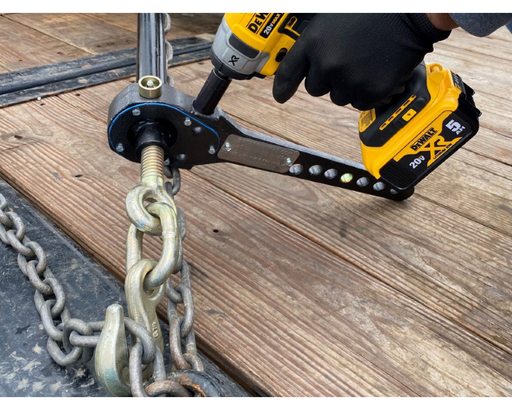

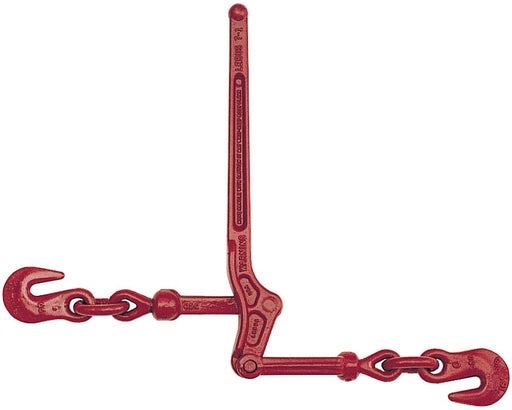

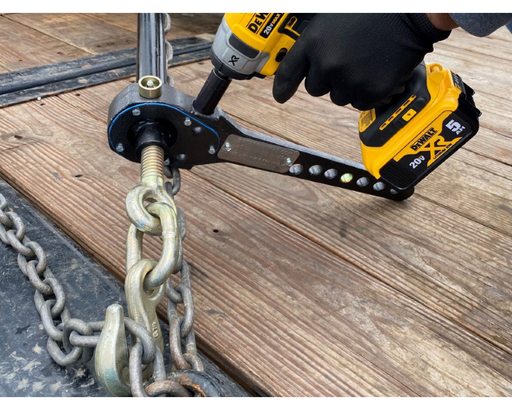

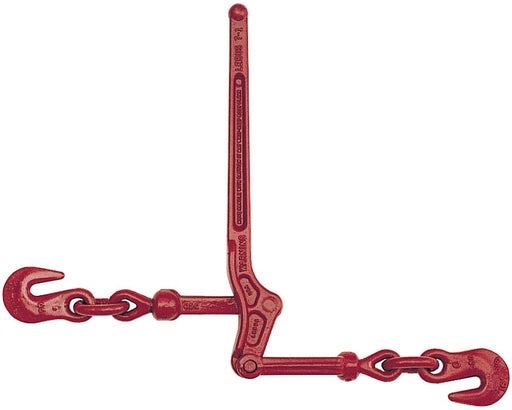

from $142.99| /Speedbinder Torque Drive Load Binder, 6,600lb ~ 13,000lb capacity

CrosbySave your drivers time and reduce strain injuries using Crosby Speedbinders torque drive binder or lashing for load securement or relocating shifte...

View full details -

Sale

from $9.93| /

Sale

from $9.93| /Crosby G209 Carbon Screw Pin Anchor Shackle, 1/2t- 55t capacity

CrosbyUSA-manufactured Crosby G209 carbon, screw pin, anchor bow shackle. Available from stock in loads 0.5 ton thro 55 ton. Designed to meet the perform...

View full details -

Sale

from $14.33| /

Sale

from $14.33| /Crosby G2130 Carbon Bolt Anchor Shackle, 1/3t- 35t capacity

CrosbyUSA manufactured Crosby G2130 carbon bolt anchor bow shackle used in rigging & lifting applications worldwide. The anchor bow style accommodate...

View full details -

Sale

from $42.65| /

Sale

from $42.65| /Crosby G2140 Alloy Bolt Type Shackle, 2t- 175t capacity

CrosbyForged alloy steel bow shackle manufactured in the USA. Similar to the G2130 version but superior alloy steel construction means maximum capacity v...

View full details -

Sale

from $208.00| /

Sale

from $208.00| /Crosby Lebus L-140 Standard Ratchet Type Load Binders, 8,800lb- 16,000lb capacity

CrosbyGet accurate tie down on your loads with Crosby Lebus L-140 racket load binders. Complete with new one-piece forged handle, this product has been ...

View full details -

Sale

from $271.00| /

Sale

from $271.00| /Crosby McKissick 418 Light Champion Snatch Blocks, 2t- 15t capacity

CrosbyCrosby McKissick 418 Snatch Block with hook. Unique opening feature permits insertion of rope while block is suspended from gin-pole or other mount...

View full details -

Sale

from $65.70| /

Sale

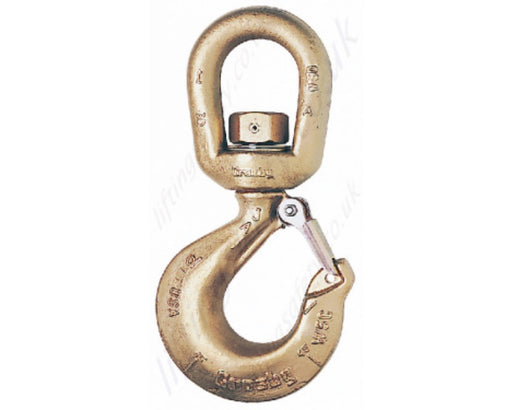

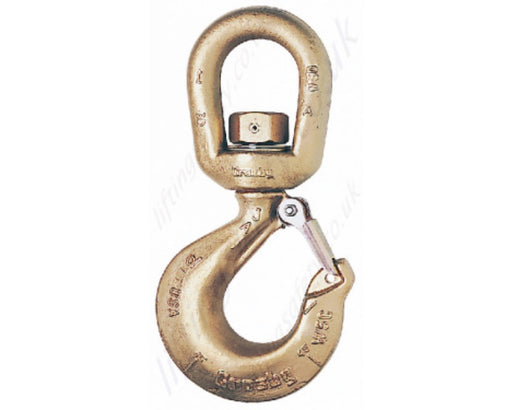

from $65.70| /Crosby S-322AN Alloy Steel Swivel Hook, 1t- 30t capacity

CrosbyManufactured in the USA the Crosby S-322AN alloy swivel hook boasts markings forged into the hook, covering deformation and angle indicators in lin...

View full details -

Save 5%

Original price $216.30Current price $206.00| /

Save 5%

Original price $216.30Current price $206.00| /Crosby 1048468 Lebus R-10 Binder without Links and Hooks, 16,000lb capacity

CrosbyThe Crosby Lebus R-10 binder boasts the features of the standard load binder range, but without links or hooks to suit various applications. Made ...

View full details -

Sale

from $77.30| /

Sale

from $77.30| /Crosby S501 Open Swage Socket, 5 2/5t- 272t capacity

CrosbyManufactured in the USA the Crosby S501 open swage socket is a clevis style forged socket used to terminate wire ropes onto an eye. Used in appli...

View full details -

Sale

from $38.00| /

Sale

from $38.00| /Crosby 450 Red-U-Bolt Wire Rope Clips

CrosbyCrosby forged wire rope clips used to terminate a wire rope usually using a thimble. Designed meet and exceed the performance requirements of ASME ...

View full details -

Sale

from $814.00| /

Sale

from $814.00| /Crosby I and H Beam Lifting Clamp

CrosbyThe Crosby IPBHZ beam clamp is an automatic clamp used to lift and handle I or H beams. Available in capacities of 0.75t thru 12t and offering a wi...

View full details -

Sale

from $153.20| /

Sale

from $153.20| /Crosby S-1317 SHUR-LOC Clevis Hooks, 3,200lb- 59,700lb capacity

CrosbyThis Crosby Clevis Hook is easy to operate with enlarged thumb access, but there are many other benefits: Made from forged alloy steel - quenche...

View full details -

Sale

from $13.17| /

Sale

from $13.17| /Crosby M-279 UNC Forged Shoulder Type Machinery Eye Bolt, 650lb- 65,000lb capacity

CrosbyCrosby M-279 UNC shoulder eye bolt, forged in the USA, used for vertical lifting applications only as WLL is reduced when loaded at an angle. For s...

View full details -

Save 5%

Original price $165.27Current price $157.40| /

Save 5%

Original price $165.27Current price $157.40| /Crosby S-1311N Chain Shortener Links

CrosbyCrosby grade 10 chain shortening link used when adjustment of chain slings or lashing chains is required. Also connects to the Crosby Straightpoint...

View full details -

Sale

from $140.20| /

Sale

from $140.20| /Crosby S-1316 SHUR-LOC Eye Hooks, 3,200lb- 59,700lb capacity

CrosbySHUR-LOC Eye Hook features: Forged alloy steel - quenched and tempered. A recessed trigger design is flush with the hook body, to protect the tr...

View full details -

Sale

from $792.00| /

Sale

from $792.00| /Crosby IPTKU Beam Clamp, 2t- 10t capacity

CrosbyThe Crosby IPTKU series beam clamp has an improved hinged hoisting eye that increases the loading angles and an optional new “Double Locking Device...

View full details -

Sale

from $130.00| /

Sale

from $130.00| /Crosby McKissick S-421T TERMINATOR Wedge Socket, 3 3/10lb- 71 1/2lb capacity

CrosbyCrosby McKissick S-421T TERMINATOR wedge socket for terminating wire ropes for connection to crane block or fixed point. Secures the tail or “dead...

View full details -

Sale

from $86.70| /

Sale

from $86.70| /Crosby SL-150 UNC Slide-Loc Lifting Points, 1/2t- 3 1/5t capacity

CrosbyManufactured in the USA the Crosby SL-150 Slide-Loc lifting points are designed for quick attachment to engineered pick points on loads, without th...

View full details -

Sale

from $174.50| /

Sale

from $174.50| /Crosby Lebus L150 Load Binder, 5,400lb- 13,000lb capacity

CrosbyManufacturerd in the USA, Crosby Lebus L150 load binder, used for safe and secure transportation of heavy loads. Construction at the leverage poin...

View full details -

Sale

from $51.50| /

Sale

from $51.50| /Crosby A-342 Alloy Master Link, 7,400lb- 336,000lb capacity

CrosbyCrosby A-342 alloy Masterlink, manufactured in USA and considered the gold standard within the rigging and lifting industries. Manufactured from al...

View full details -

Sale

from $833.00| /

Sale

from $833.00| /Crosby IPSC Positioning Screw Clamp, 1 1/2t- 3t capacity

CrosbyThe Crosby IPSC10 screw style clamp is used for positioning, pulling and turning plates or fabrications. Available in capacities of 1.5 and 3 met...

View full details -

Save 5%

Original price $7,138.95Current price $6,799.00| /

Save 5%

Original price $7,138.95Current price $6,799.00| /Crosby 2734009 CCBG Clamp-Co Concrete Barrier/Curb Grab, 4 1/2t capacity

Crosby4.5 ton capacity Crosby Clamp-Co Barrier Grabs provide a fast and efficient method of handling concrete road barriers. Hands-free operation Alloy ...

View full details -

Sale

from $2,763.00| /

Sale

from $2,763.00| /Crosby IPBCNS Beam Lifting Clamps

CrosbyCrosby IPBCNS Beam Lifting Clamps enable the lifting and transfer of wide flange beam sections and plate girders. When lifting, these beam clamps g...

View full details -

Sale

from $800.00| /

Sale

from $800.00| /Crosby IPBC Horizontal Beam Clamp, 1t- 4 1/2t capacity

CrosbyThe Crosby IPBC horizontal lifting clamps have a pretension feature that allows the user to attach the clamps to the material for horizontal liftin...

View full details